Structural Steel Detailing

Structural Steel detailing services is another name of communication link or drawings between designer and shop fabricators. Structural Steel Detailed is integrated with the detailed Drawings for the Steel Manufacturers, steel erector, or steel fabricators to use in the construction industry this drawing required 99.9%

- Home

- Services

- Structural Modeling Services

- Structural Steel Detailing

Structural Steel Detailing

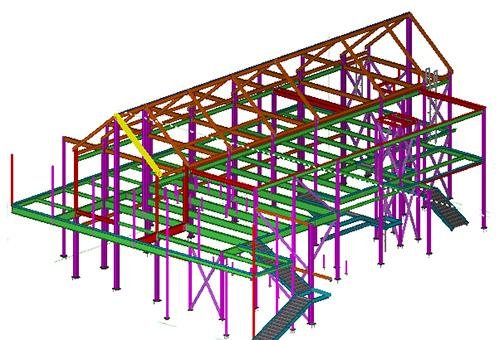

We are one of the leading companies for delivering micro-precision and accurate steel detailing services worldwide. Our steel detailing services includes shop drawings, working drawings, and GFC drawings with their respective 3D Models. Our team has high-quality knowledge in steel detailing software such as Tekla structure for developing 3D Models as well as Develop Effective and Efficient Drawings At the cross-sectional level. It is a critical structural engineering process and requires nearly 99% accuracy.

Even a small mistake can lead to a waste of valuable time and money. Structural steel detail is an important and mandatory process in all types of manufacturing and construction activities, such as the construction of residential and commercial buildings, factories, and institutes. We provide steel detailing services to customers all over the world. Talk to our experts to get detailed information about our Structural Steel Detailing Services.

Benefits of Structural Steel Detailing

Accuracy & Precision

Structural steel detailing ensures high accuracy in dimensions and connections, reducing errors in fabrication and assembly.

Time & Cost Savings

By providing detailed drawings and a clear workflow, it minimizes rework, reduces material waste, and enhances project efficiency.

Improved Fabrication

Detailed shop drawings streamline the manufacturing process, making fabrication and on-site assembly faster and more efficient.

Structural Integrity

Proper detailing ensures strong and reliable structures, reducing the risk of failures and increasing safety.

Project Coordination

It facilitates seamless communication between architects, engineers, and fabricators, improving project management.

Optimized Material Usage

Structural detailing helps in precise material estimation, reducing waste and ensuring cost-effective construction.

Facilitates Prefabrication

Enables off-site fabrication, reducing on-site labor, speeding up construction, and improving quality control.

Enhanced Visualization

3D models and detailed drawings give a clear representation of the final structure, aiding decision-making

General Questions

1. What is Structural Steel Detailing?

The process of creating precise drawings and fabrication plans is essential for the construction of steel frameworks. These documents, often referred to as shop drawings, contain all the necessary details fabricators need to manufacture components like beams, columns, braces, plates, and connections. Contractors then use these detailed plans to assemble and install the steel structures on-site. This workflow ensures that every part fits perfectly, aligns with design specifications, and adheres to relevant building codes and safety standards.

2. Why is Structural Steel Detailing Important?

Creating detailed steel fabrication drawings is essential for several reasons:

- Ensures Accuracy: Detailed drawings ensure that each steel component is fabricated to the correct specifications, reducing the likelihood of errors.

- Improves Communication: It serves as a communication tool between engineers, architects, fabricators, and contractors to ensure all parties are aligned on the design and construction processes.

- Facilitates Fabrication and Installation: Shop drawings provide clear instructions on how to manufacture and assemble steel components, making the fabrication and installation process more efficient.

- Ensures Structural Integrity: Detailing ensures that the steel components fit together properly, which is critical for the safety and stability of the building.

3. What Are the Benefits of Structural Steel Detailing?

The key benefits of steel fabrication drafting services include:

- Precision and Accuracy: Ensures that all steel components are fabricated to exact specifications, reducing the risk of errors and rework.

- Reduced Construction Time: By providing clear instructions for fabrication and installation, detailing speeds up the construction process and reduces delays.

- Cost Efficiency: Detailed drawings minimize the chances of costly mistakes or change orders, helping to keep the project within budget.

- Enhanced Coordination: Helps coordinate the work of different trades (e.g., electrical, plumbing, and HVAC) by detailing how steel components interact with other building systems.

- Compliance with Codes: Ensures that all steel components meet industry standards and regulatory codes, improving safety and structural integrity.

4. What is the Process for Structural Steel Detailing?

The process for structural steel detailing generally follows these steps:

- Review Design Drawings: The detailing team begins by reviewing the architectural and structural design drawings to understand the overall design intent.

- 3D Modeling: Using software tools like Tekla Structures, AutoCAD, or Revit, a 3D model of the steel structure is created, helping to visualize how the components will fit together.

- Detailed Drawing Creation: The detailer generates shop drawings, including precise dimensions, connection details, and fabrication instructions for each steel component.

- Coordination with Other Trades: During the detailing process, the team checks for potential clashes or conflicts with other building systems and ensures the steel structure fits seamlessly with the overall design.

- Review and Approval: The detailed drawings are submitted to the structural engineer, architect, or general contractor for review and approval.

- Finalization of Drawings: After any necessary revisions, the final shop drawings are released for fabrication and installation.

5. What Software is Used for Structural Steel Detailing?

Several software programs are commonly used for structural steel detailing, including:

- AutoCAD: A widely used 2D and 3D drafting software for creating shop drawings and detailing steel structures.

- Tekla Structures: A powerful BIM (Building Information Modeling) software used specifically for structural steel detailing. It allows for 3D modeling and generates detailed drawings directly from the model.

- Revit: A BIM platform that supports both architectural and structural design and detailing, including steel structures.

- Strucad: A 3D modeling and detailing software used for structural steel projects.

- SolidWorks: Used for designing and detailing custom or intricate steel components.

- Bentley ProStructures: A software suite for creating 3D models and detailed drawings of structural steel elements.

6. How Much Do Structural Steel Detailing Services Cost?

The cost of structural steel detailing services depends on several factors:

- Project Size and Complexity: Larger and more complex projects require more time and resources, which increases the cost.

- Level of Detail: Detailed, custom steel components or intricate designs require more time to detail, resulting in higher costs.

- Scope of Work: The amount of work involved, including 3D modeling, custom detailing, and revisions, will influence the cost.

On average, structural steel detailing services may range from $2,000 to $15,000 or more, depending on the project’s complexity and size.

Enquire Now

Our Work